PolyDox™ Near-Wellbore Water Control Gel

One-Stop Gel System for Conquering Challenges

Our advanced POLYDOX™ gel technology introduces a high-strength, precisely crafted artificial polymer gel. This groundbreaking gel possesses exceptional capabilities, allowing it to efficiently penetrate the matrix before the gelation process begins.

POLYDOX™ gel stands out as a versatile solution with a range of applications. Its primary role involves water shutoff, including tackling issues such as near-wellbore and high-permeability channeling, along with zone abandonment. Furthermore, it demonstrates exceptional proficiency in sealing openhole sections during vertical or short-radius horizontal recompletions.

Innovative Polymers for Robust Water Control

DOSAS Polymer Gel Technology

Rigid Gel Polymer, a Permanent Solution for Water Shut Off

Ultra-Low Molecular Weight Polymer

Its low molecular weight allows efficient penetration of small pores, ensuring optimal effectiveness.

Stable Under High Shear Pressure

Given its low viscosity, concerns regarding polymer chain breakage are substantially mitigated.

Stability with Hydrogen Sulfide

Owing to its special formulation, it possesses a perfect adherence even in long-term contact with H₂S.

Mix-water Hardness and Salinity

This solution remains stable against divalent cations at temperatures over 70°C, despite water hardness.

Ground Field Case Study

Precision Empowered, Mastering Gel Solutions

PolyDox™ was implemented as a water control technology in the Middle East to address the abandonment of zones invaded by injection well channeling, which resulted in a 93% water cut and a permeability of less than 5mD. The steps taken included re-establishing isolation, correcting the channeling behind the casing, and recompleting in new intervals containing hydrocarbons. Initially, after adding PolyDox™, the water cut was reduced, and oil production increased twofold.

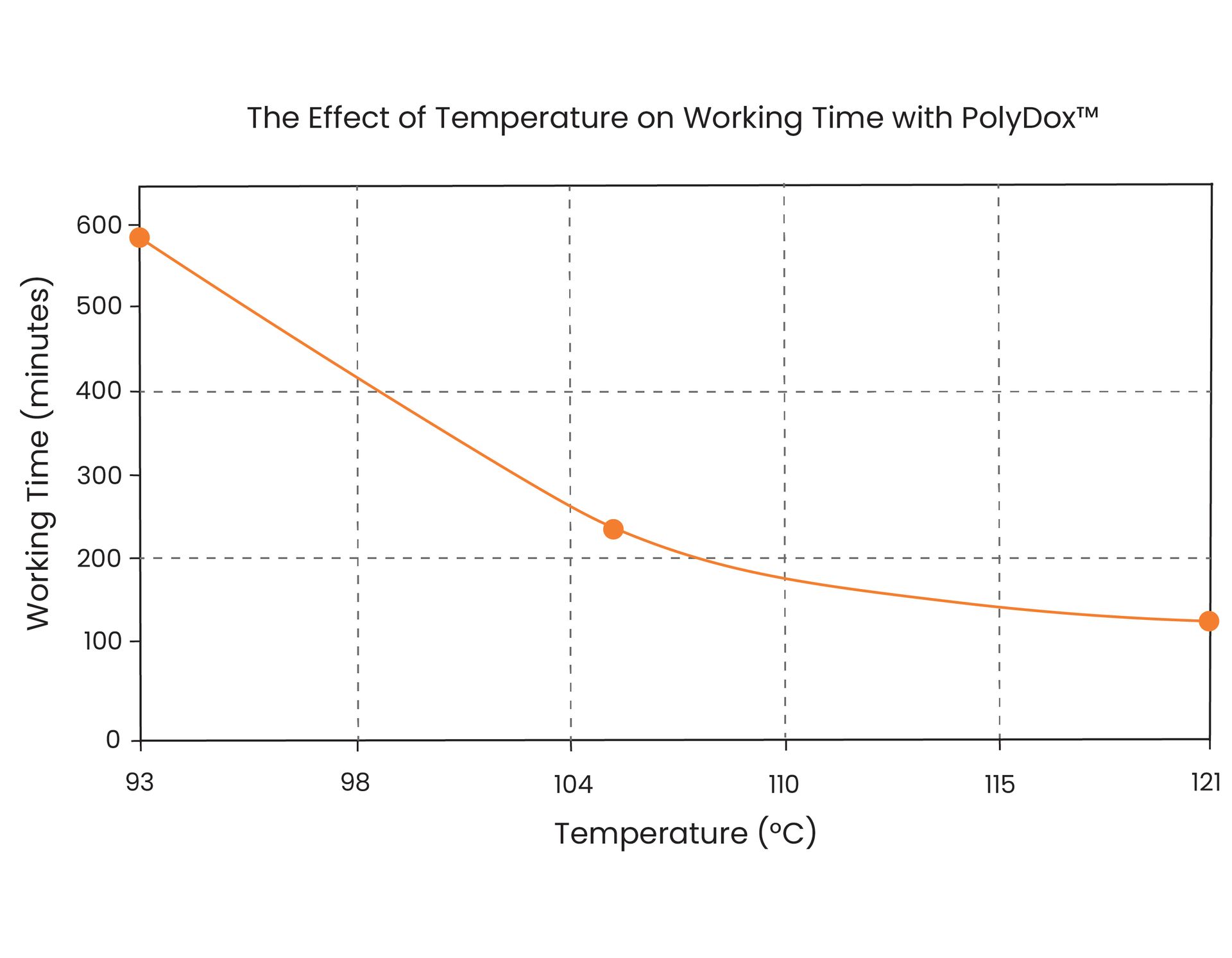

Controlled Gel Working Time

Unlocking Precise Control Over Gel Working Time

We’ve perfected gel working time manipulation, offering unmatched flexibility in reservoir temperatures. Our solutions allow you to adjust working times between 1 to 24 hours by engineering design in polymer concentration and also modifying gel activator presence and concentration. PolyDox™ is ideal for reservoir applications with bottomhole static temperatures (BHSTs) up to 250°F (121°C). This polymer also integrates seamlessly into matrix with permeabilities of 30mD or greater, showcasing its adaptability and effectiveness.

Precision Analysis and Tailored Solutions

We at DOSAS, take pride in our exceptional capabilities dedicated to gel performance analysis. Our state-of-the-art facility empowers us to meticulously control gelling time, gel extrusion resistance, gel stability ensuring the perfect balance between setting and flexibility. We're equipped to determine precise gel working times for both mixing and pumping, enabling us to fine-tune our solutions to your unique requirements.

Operational Flexibility

Dosas proudly unveils a range of rigid gel polymers for near-wellbore applications. PolyDox™, with its complex formulation, demonstrates a high success rate in gas shut-off when followed by cement with a freshwater spacer.

For more detailed technical specifications and to discuss how our product can be tailored to your specific needs, please contact our technical support team.

GET IN TOUCH WITH AN EXPERT

Thank you for contacting us!

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.

Oops,

There was an error sending your message.

Please try again later.

About Dosas

Helpful links

Further Information

Hofplein 20

Rotterdam 3032 AC

The Netherlands

Phone: +31 103 40 1900

Email: Info@dosas.nl

Copyright DOSAS All Rights Reserved

In addition to technically necessary cookies, we also use cookies whose purpose is to analyze website access or personalize your user experience. You can revoke your consent to their use at any time. Information on the cookies used and your right of revocation can be found in our privacy policy.