Gelling Agent

Strategic Molecular Design for Frac Fluid Viscosifying Agents

As the exploration of oil and gas reserves pushes into increasingly harsh environments, conventional fracturing fluids are encountering significant limitations. High-temperature, high-pressure, and deep formation conditions demand innovative solutions that go beyond the capabilities of traditional methods.

The DosORO™ synthetic polymer/GG blended system is a versatile solution that adapts to various operational needs. In some scenarios, it serves as a direct alternative to traditional DosORO™ GG fluids, maintaining performance while reducing costs. In others, it acts as an efficiency-boosting option, enhancing the overall effectiveness of the fracturing process.

Design Flow of Stimulation Fluid System

Boost Pump Efficiency by Synergistic Additives

Viscosifying Agent

Improve fluid rheological properties by providing sufficient viscosity.

Crosslinking Agent

Connects the polymer to form a 3D network structure by chemical bonds.

Breaker

Break the fluid into a thin liquid and finally flows back to the surface.

Guar Gum and Its Derivatives

Extended Molecular Chain

By increasing the number of hydration groups on the molecular chains, DosORO™ GG not only minimizes residue after gel breaking but also significantly improves water solubility. This enhancement allows the polymer chains to stretch and wind effectively in water, delivering a robust thickening effect. Complex groups are introduced into the DosORO™ GG chain to extend the molecular chains, reduce entanglement, and increase the crosslinking ability, further enhancing the temperature resistance of the biopolymer.

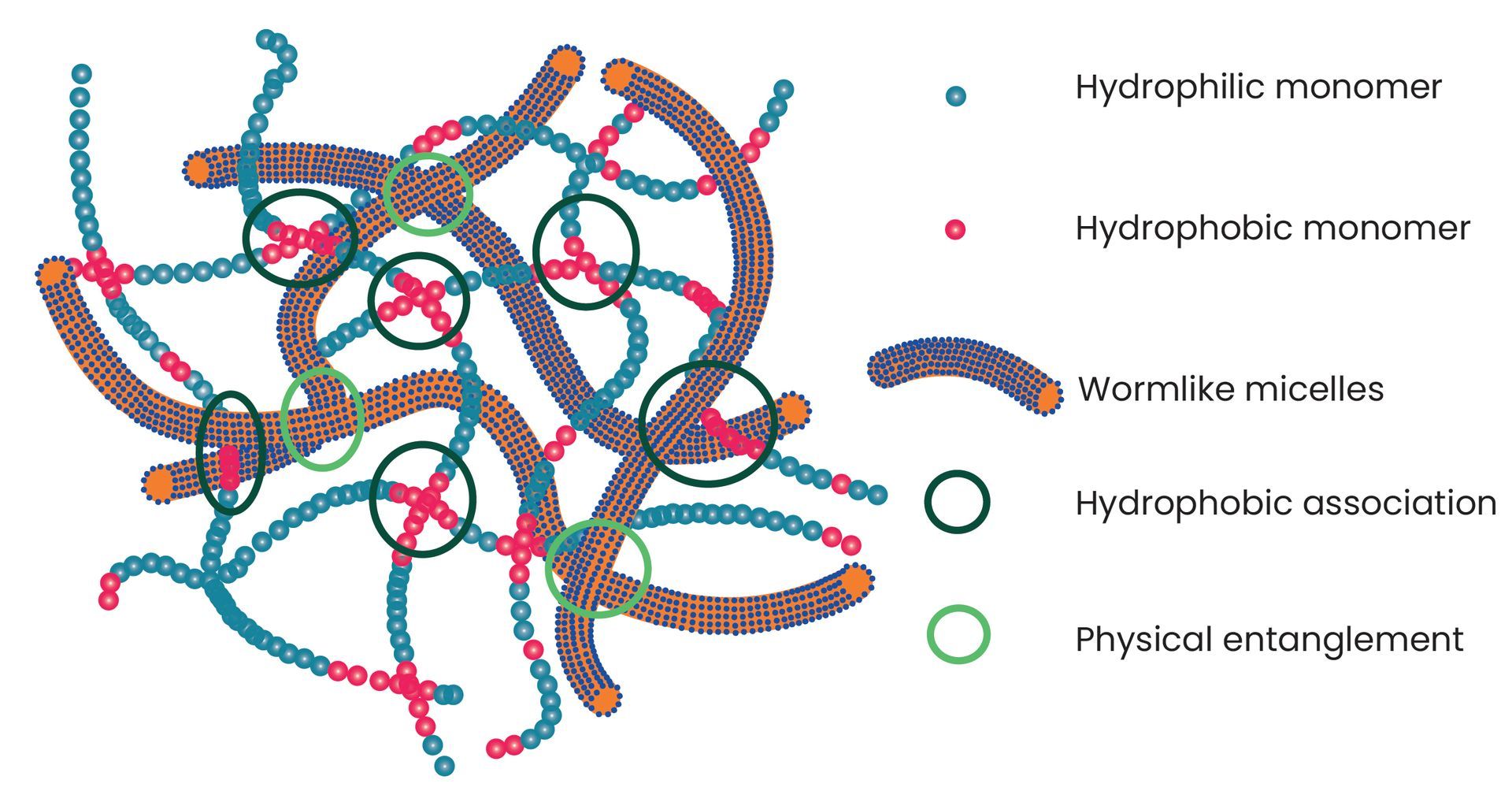

Thermoviscosifying polymer

Hydrophobic and Hydrophilic Fusion

DosORO™ polymer gelling agent structure is designed with lone electron pairs that act as crosslinking points, enabling complexation reactions that form a high-temperature-resistant crosslinked gelling agent. The presence of strong hydrophilic groups enhances water solubility by forming intermolecular hydrogen bonds, further improving the overall performance of the polymer. The inclusion of hydrophobic monomers in the molecular chain significantly boosts the polymer's rheological properties, enhancing the effectiveness of DosORO™ through modified intermolecular associations.

Acid Gelling Agent

Thickener Efficiency in Acid Stimulation

DosORO™ AG is an efficient viscosity builder and has good stability in 15% HCl at temperatures up to 150°F. Computer model studies, which take into consideration cool-down and gel degradation rate at various stages of acid spending, indicate viscosity is maintained when treating wells that have bottomhole temperatures (BHT's) up to 220°F. Since the gelled acid retains its viscosity during spending, both reaction rate and fluid leakoff are retarded.

Gel Stabilizer for Fracturing Fluids

GeliN™ sulfur-free gel stabilizer is designed to improve the stability of fracturing fluids, ensuring optimal performance even under high-temperature conditions. Unlike conventional stabilizers that contain sulfur, our product is non-hazardous, biodegradable, and provides superior stability

GET IN TOUCH WITH AN EXPERT

Thank you for contacting us!

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.

Oops,

There was an error sending your message.

Please try again later.

About Dosas

Helpful links

Further Information

Hofplein 20

Rotterdam 3032 AC

The Netherlands

Phone: +31 103 40 1900

Email: Info@dosas.nl

Copyright DOSAS All Rights Reserved