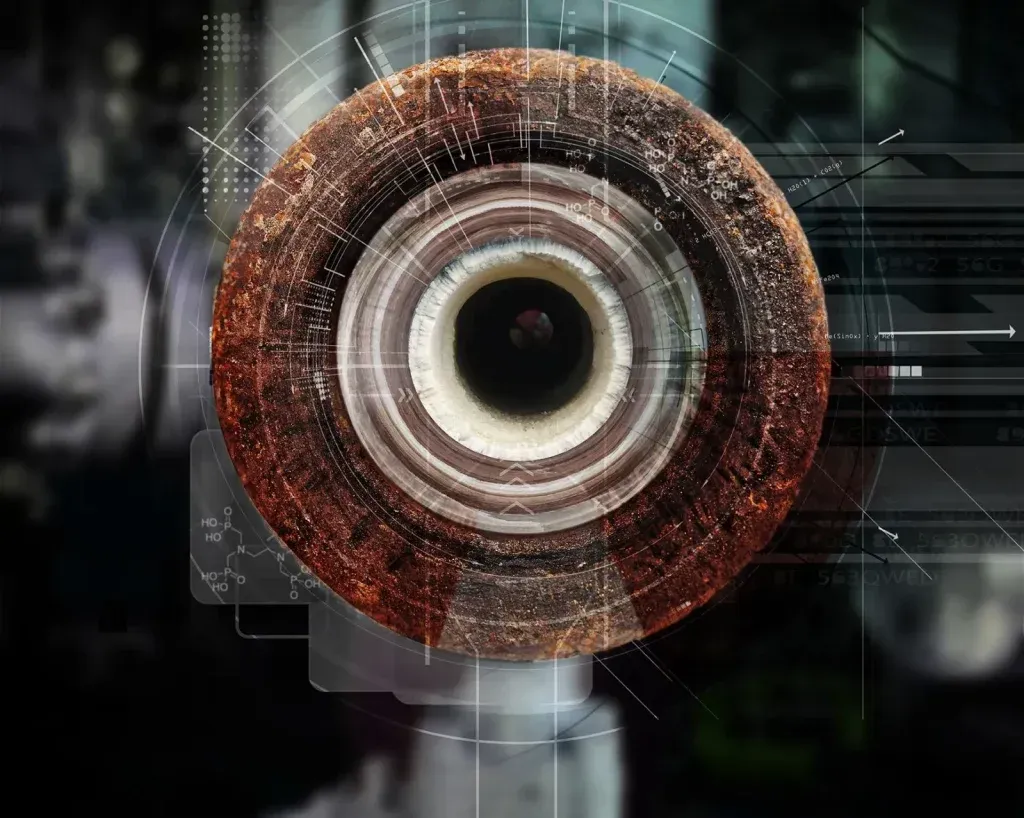

CorFix™ 9113 Corrosion Inhibitor

Overhead Line Corrosion Inhibitor & Emulsion Breaker

CorFix™ 9113 Corrosion Inhibitor

Distillation Column Overhead System Film Forming Corrosion Inhibitor

Corrosion in refinery crude distillation units is a common industry problem. Acids or salts present in the distillation column overhead system may cause corrosion when the right conditions exist. CorFix™ 9113 polar group attaches to the metal surface, while the hydrocarbon skeleton forms a hydrophobic layer that repels water molecules and subsequently retarding corrosion reactions. Attractive characteristics of CorFix™ 9113 include high protection at lower dosages; meet all practical requirements such as low emulsion and foaming tendencies, thermally stable, and does not lead to plugging; and is desired especially in locations in the refinery that experience high flow velocities and shear forces.

Performance Highlight

New Paragraph

New Paragraph

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

Get in Touch with an expert | CorFix™ 9113 Corrosion Inhibitor

Related Products