ORIFICE™

High-Temperature Solutions for Near-Wellbore Challenges

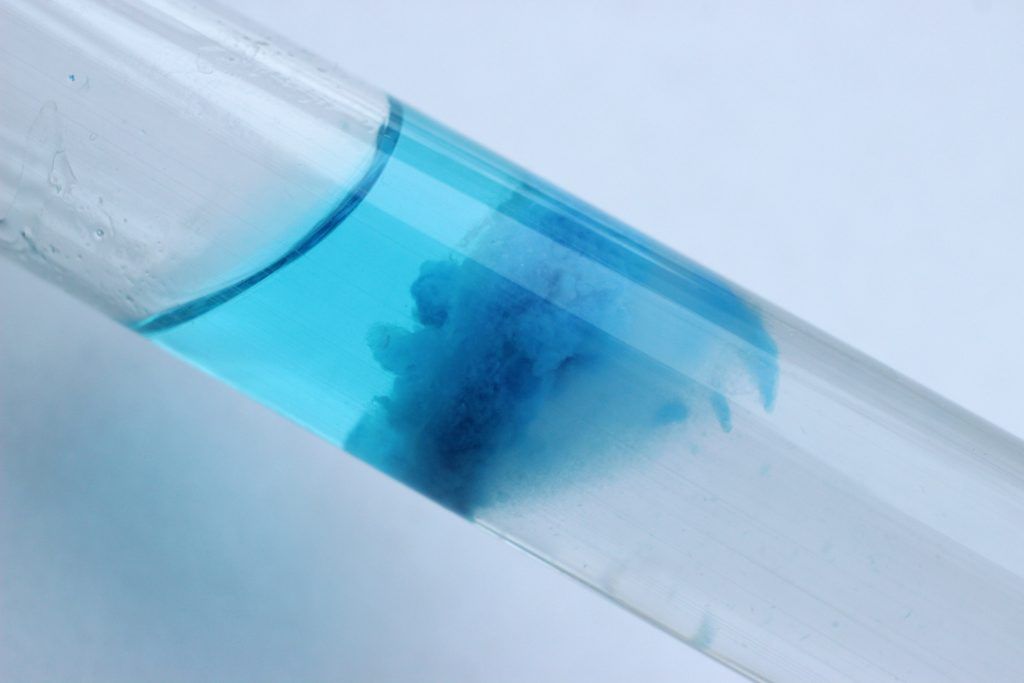

ORIFICE™ Near-Wellbore Water Control Gel

Engineered for Exceptional Gel Strength and Versatility

ORIFICE™ boasts precisely engineered polymers and crosslinkers, making it the ideal choice for applications where robust bulk gel strength is paramount. Its unique formulation owns exceptional control over gel working time and is particularly beneficial for low and high permeabilities. It is also a perfect choice for cement bond failures.

When the need to remove ORIFICE™ arises, straightforward mechanical processes such as high-pressure water jetting, workover string, or coiled tubing effectively clear the wellbore. In situations where mechanical processes are insufficient, we offer a range of chemical wash solutions as effective alternatives.

Performance Highlight

Doubling Oil Recovery with Innovative Solutions

Soon after being brought into production, two wells in North Africa were yielding less than 15% oil at a well temperature of 140°C due to an excessive water cut. The operator ultimately decided to shut down both wells ahead of schedule. Initially, ORIFICE™ was deployed as a solution. Results showed a 60% to 80% reduction in water cut, and oil production increased by more than twofold.

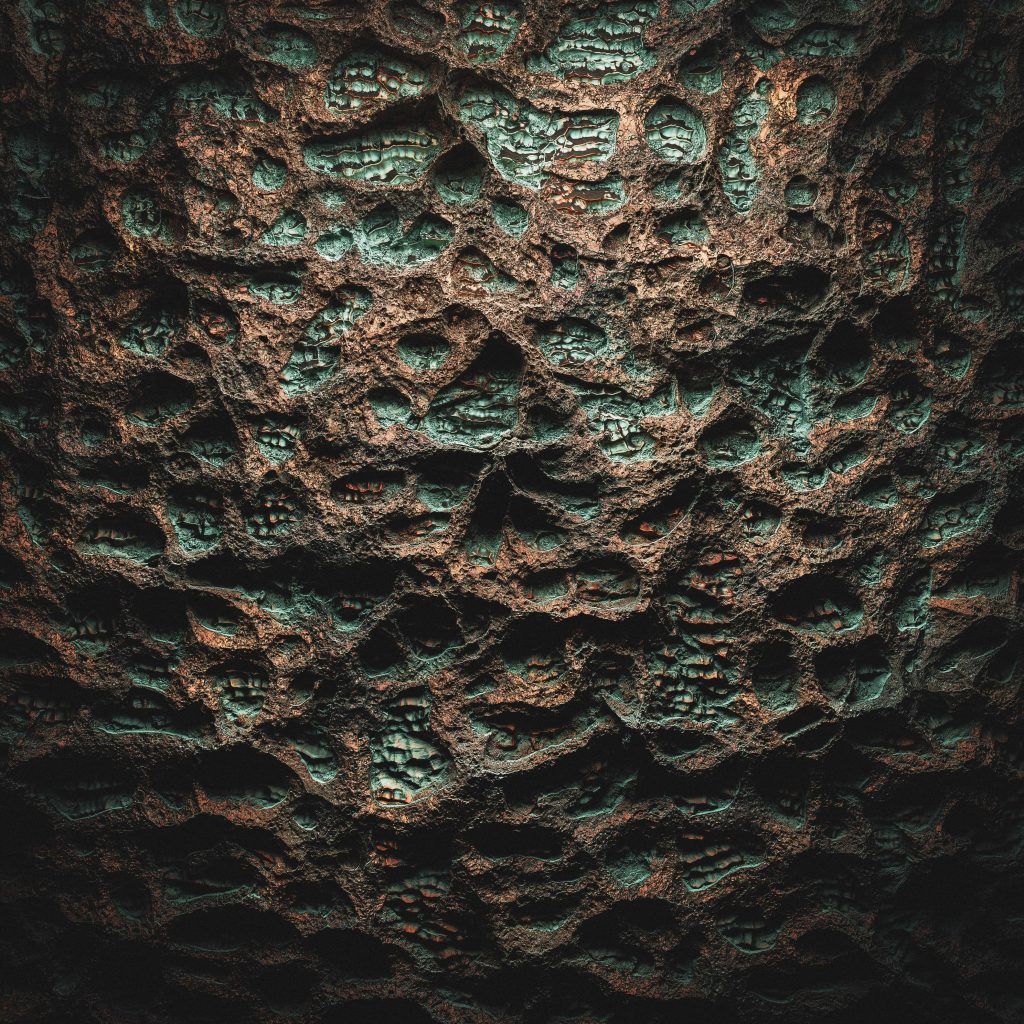

Gel Penetration

ORIFICE™ owns an ultra-low molecular weight polymer in its formulation, which allows efficient penetration of small pores, ensuring optimal effectiveness.

Gel Working Time

One of the remarkable features of ORIFICE™ is its exceptional control over gel time, making it suitable for a wide range of reservoir applications.

Temperature Range

ORIFICE™ is formulated gel that can withstand bottomhole standard temperatures (BHSTs) of up to 149 °C.

Hydrogen Sulfide Resistance

ORIFICE™ is chemically designed to have a perfect resistance over H₂S even in long-term contact.

Get In Touch with An Expert | ORIFICE™

Related Products