Spacer Solution

Package of Suspending Agent, Surfactant and Solvent

Cement Drilling Fluid Spacer

Spacer Design Where the Cement Slurry Displace a Non-Aqueous-base Drilling Fluid

DosPex™ is a comprehensive package of spacer suspending agents, surfactants, and solvents designed to optimize drilling fluid removal and enhance well integrity. By delivering efficient cleaning and emulsion inversion, DosPex™ improves cement-to-casing bonding through superior hole cleaning. Additionally, it minimizes the impact on cement slurry thickening time and compressive strength development.

DosPex™ solution focuses on three key performance areas: gel prevention, fluid loss control, and lost circulation prevention, ensuring reliable and efficient cementing operations.

DOSAS Spacer Package Design for Efficient Cleaning and Emulsion Inversion

Synergizing Spacer Package based on type of NAF base Oil, Temperature, and Salt Content

Suspending Agent

Suspending the weighing agents particles and prevent sedimentation

Dispersing and reversing the drilling fluid emulsion, and leave the casing water-wet

Clay Stabilizer

Inhibit the swelling of formation clays thereby preventing damage by spacer

Carrier Fluid & Solvent

Clean most polar, small-carbon chain, to highly apolar, long-carbon chain oils

DosPex™ Gel Prevent Spacer

DosPex™ Spacer Prevents Gelation of the Drilling Fluid and Cement Slurry

DosPex™ prevents gelation and hard setting caused by several phenomena influencing cement behaviour including:

- High Solids Volume Fraction (SVF): Increased SVF significantly raises the risk of gelation.

- Weighing Agent Flocculation: At temperatures exceeding 100 °C, weighing agents tend to flocculate, leading to stability issues.

- Cement Contamination: Cement contamination intensifies the risk of spacer gelation, compromising operational efficiency.

DosPex™ ONE Spacer

Prevents Rapid Cement Dehydration and Maintain Constant Rheological

DF removal is a critical step in primary cementing operations. The failure to remove circulatable drilling fluid is often a cause of cementing failures, fluid migration behind the casing, poor cement bonding, and production from unwanted zones.

DosPex™ ONE Spacer help minimize fluid losses into a formation by forming a film or filter cake on the formation surface and dispersing the particles in the slurry.

DosPex™ Lost Circulation Prevent Spacer

Adjustable Rheology Cement Spacer Engineered to Stop Lost Circulation

Most oil-base and synthetic-base drilling fluids are incompatible with cement slurries. Commingling of the DF and the cement slurry may result in the buildup of an unpredictable and viscous sludge at the mud/cement interface. The added buildup of displacement pressure caused by the sludge can itself become a serious problem by causing lost circulation of the cement slurry. The DosPex™ cement spacer is an adjustable rheology cement spacer engineered to stop lost circulation during primary cementing before it starts prevents unpredictable thickening time and set properties.

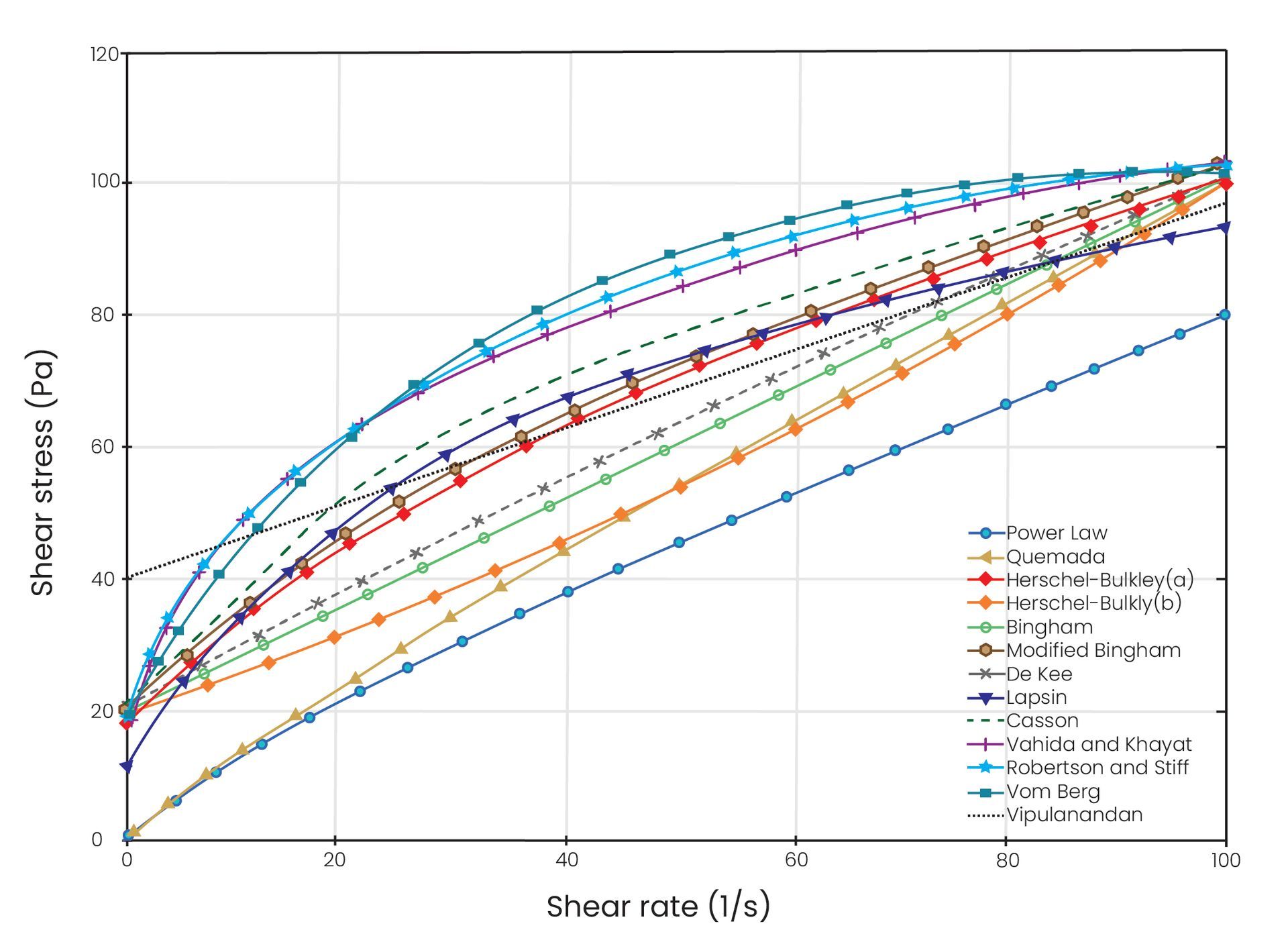

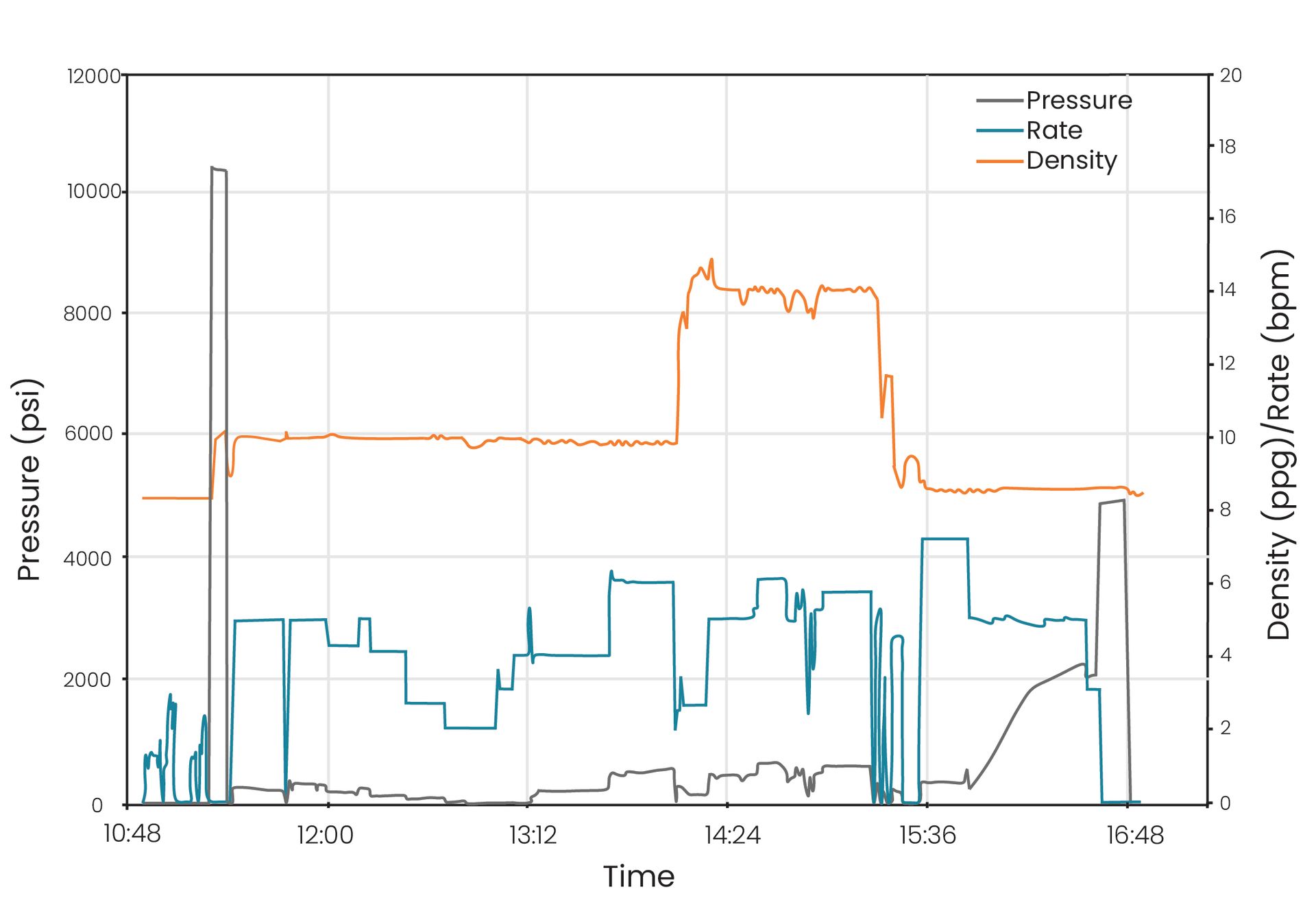

Simulate the Complex Behaviour of Spacer and Wellbore Fluids

At DOSAS, we specialize in designing the best-in-class spacer for cementing operations. Our comprehensive testing capabilities include:

- Rheological Property Analysis: Assessing fluid flow behaviour for optimal performance.

- Gel Strength Evaluation: Ensuring effective gelation to prevent fluid migration.

- Thickening Time Measurement: Determining the ideal setting time for cement slurries.

- Compressive Strength Testing: Verifying the mechanical integrity of set cement.

- Solids Suspension Testing: Ensuring uniform distribution and suspension of solids.

- Spacer Surfactant Screening: Selecting the most effective surfactants for efficient displacement.

Spacer Surfactant Design

DosSurf™ series are formulated surfactants promote water-wetting properties for maximum cement bonding to formation and pipe and robustly work with different types of invert emulsion drilling fluids under various range of temperature, salinity, and non-aqueous base fluids.