PERMOLEAN™

Flowing Solutions, Maximum Reservoir Potential

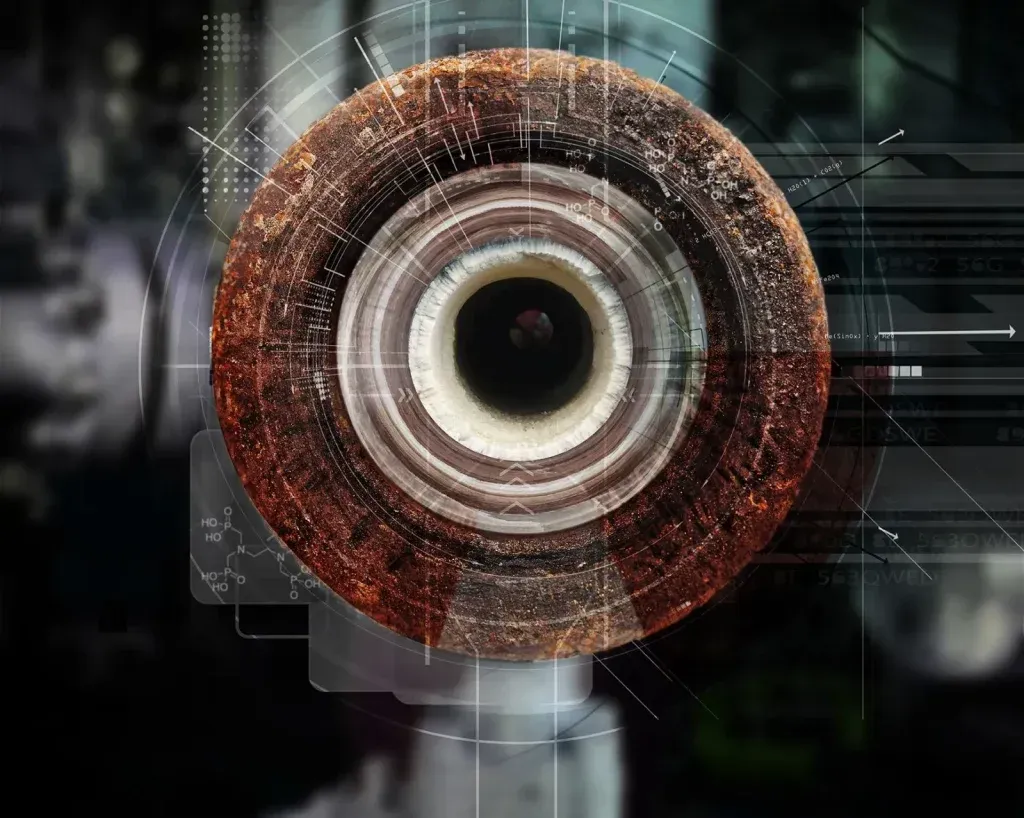

PERMOLEAN™ Fracture Water Control Gel

Advanced Gel Designs for Enhanced Fissure Penetration

PERMOLEAN™, with its precision-controlled molecular weight, boasts a unique characteristic: it is intentionally engineered not to penetrate the matrix. This specialized flowing gel is purpose-built for tackling reservoir challenges where traditional matrix penetration isn't required.

The key to PERMOLEAN's success lies in the choice of suitable molecular weight polymers, which significantly limit leakoff into the matrix, ensuring a higher viscosity per polymer concentration.

In the treatment process, crosslinking occurs early, further enhancing leakoff reduction and elevating fissure penetration efficiency. This crosslinked material takes the form of a flowing gel, specifically engineered to retain its ability to penetrate natural fractures.

Performance Highlight

Enhancing Water Conformance in Hardwater Reservoirs with High Water Cut

PERMOLEAN™ was implemented in the Middle East in a fissure reservoir with a 98% water cut and high salinity, due to hardness-related divalent cations, in a low-temperature bottomhole (BHST). PERMOLEAN™ maintains perfectly stable formulations designed for in depth reservoirs, which allowed this project to achieve an impressive increase in oil production within 60 days after injection.

Temperature Range

PERMOLEAN™ shines in diverse environments, comfortably accommodating bottomhole static temperature (BHSTs) spanning from 21 to 109°C.

Chemical Stability

PERMOLEAN™ owns a compatible formulation that makes it suitable for high water cut results in fissure-dominated production.

H₂S Stability

PERMOLEAN™ offers exceptional stability, even with prolonged exposure to H₂S. Its resilience ensures reliable performance over time.

Get In Touch with An Expert | PERMOLEAN™

Related Products